Creating Trayvax Products: What is a Tumbler?

As a regular consumer of the Trayvax Blog one understands that our underlying company goal is this special moment in time. A moment that could potentially be decades away but as a minimalist company we have been preparing for it since we started creating products. It is the moment when one generation passes a Trayvax product onto the next generation, telling stories of all the adventures it has been on. Thus encouraging the next generation to continue their own story for their newly acquired heirloom product.

For us to succeed in this timely goal, we need to make products that can last a lifetime. And not the journey of a single lifetime, but ideally multiple generations.

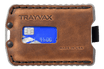

This means our products need to be durable from the beginning. The products need to be designed to feel spectacular in your hand, functional in its purpose and sleek in its profile. This is why, at Trayvax, we put all of our finished metal products through an extensive tumble process to achieve a smooth finish. Pledging the question…

What is a Tumbler?

After our American sourced metal is cut and ready to be hand-assembled into a product, there is a process called tumbling that takes place in between. The reason we tumble the metal is to remove any dirt built up or any small sharp metal fragments, called burrs.

A tumbler is a massive drum that rolls product, water and media together. Tumbling media is an abrasive material used for polishing, it looks like little stones that are smooth to the touch.

As we run the tumbler for hours the metal clashes against the media and other pieces of metal drop microscopic sediment to the bottom of the water. A process called deburring.

Why Spend All That Time To Tumble?

The tumbler is a lengthy process but creates a much softer end product that can be seen in all Trayvax products. Have you ever had a piece of clothing get snagged on a metal product? After inspecting you realized there is a tiny piece of metal that snagged it. These metal burrs can be a major pain, especially on a metal wallet you are sliding in & out of pockets or a Cinch Belt you are tucking cotton shirts into.

We want to make products that our customers are proud to use. At Trayvax, we inspect every product multiple times by different employees during the creation process to ensure only the highest quality is sent out the warehouse doors. Of course we are going to spend the extra tumbling effort to make sure our product is smooth to touch, dirt and oil free and polished to hold appearance for decades to come.

The Tumbling Process:

While the tumbler process is incredibly important it can take up to 12 hours for one tumble cycle and even then some material needs to be re-tumbled. To start, we receive the metal product from American resources. At first, they have sharp edges from being stamped and cut during manufacturing. Our goal is a uniform polished finish so we add them to our main tumbler. We have two tumblers varying in different types of media and size to provide for unique finishes.

For hours the tumbling media, metal products and water slush around bumping into each other as the tumbler continues spinning. Metal sediments and dirt drop to the bottom of the tumbler creating slag water. We then filter the slag water for burr removal, allowing us to remove the unwanted material whilst keeping the water cleaner.

When the metal is cleaned and polished to the desired touch we drain the slag water and remove the freshly polished metal. We place the product on the drying racks for several hours. Then it is inspected for burrs or dirt that was not removed, hand polished and separated into “ready to be assembled” and “needs to be re-tumbled” piles. A small percentage does need to be re-tumbled because we need to be certain every product is free from burrs or any other imperfections.

The finalized metal is then stocked as product inventory and eventually handmade into a product.

Tumbler Process Summary:

-Receive Product

-Main Tumbler, Secondary Tumbler

-Water filtered out for burr removal

-After a few hours tumbling the product is ready to start drying for a several hours

-Clean, polished & confirmed no need to re-tumble

-Ready to be assembled

Cheers,

Brian Z - Trayvax Content Creator

support@trayvax.com

2 comments

Srinivas

Nice blog. A suggestion if I may. You guys should start serializing the metal chassis. Basically add a serial number on the chassis. It would be cool to associate the serial number with the individual owner just as a legacy. Of course such a registry can be used for property tracking as well. But as a long lasting product, it’s something we can appreciate.

Anyway, keep making the great product.

Mike Bohling

Very cool ! I like the fact that we get too know the names of the people who assem your products.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.