Our ancient ancestors have used leather for dozens of generations by making clothing or shelter to keep warm. Today leather is used across multiple industries and made in a similar way we did all those years ago. Even though the process has not changed much since the medieval times we depend on it now more than ever. Imagine a fashion or sports world without leather!

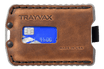

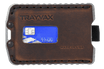

Genuine leather means the material came from an animals rawhide originally. Artificial leather, also known as faux leather, is plastic based and then dyed to have similar characteristics. Trayvax never uses faux leather. Trayvax's leather comes from premium grade Horween Leather manufactured in Chicago. But what is the process of making full grain leather? How does it go from a grazing livestock animal to our everyday carry?

Making Leather:

Livestock that was raised for meat, dairy and wool was found to have another resource - genuine leather. Leather can be made from a wide range of animals, pigs, sheep, even crocodiles. Today the leather industry is primarily cowhide based because of the abundant access. Leather is and forever will be a by-product of the meat and dairy industry, thus it would be destroyed if not used. The hide of the animal is removed as the result of a skinning process and then salted to prevent it from decomposing. It is then soaked in water to remove any dirt before being soaked for multiple days in a lime bath in order to remove hair from the hide.

After the soaking process, the hide is heavy and thick and is split into two layers. Separate parts of the hide are to be used for different types of leather product. The top part of the leather split is used for the highest quality is to used for full grain leather products, like your Trayvax gear!

Tanning and Rolling:

Once the hide is prepped the next step is the tanning process which will preserve the durability of the material. The hides are loaded into tanning drums and combined with a tanning solution. After removed from soaking, the moisture needs to be removed through a process of high pressured rollers. The hides are hung to dry and checked for imperfections! Once tanned and dried for their intended purpose the leather is set to be dyed. The hides are again added to large drums in order to be dyed to preference and then hung to dry again. This could be seen in the variety of colors we offer for Trayvax wallets!

Finishing:

When the dyeing process is complete, the last stage is finishing. This is where the leather will be worked to ensure that it has the adaptable properties that is desired in leather as well as the polished finish. A finish that not only protects the surface but also one which can be cleaned easily.

Summary:

-Genuine Leather comes from animals, faux(fake) leather is plastic based

-Converting rawhide to leather is the process of soaking and drying

-Tanning preserves the durability and color

Cheers,

Brian Zig - Trayvax Content Creator

Browse Trayvax Wallets

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.