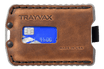

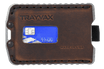

Trayvax is officially more than a wallet company. Announcing the release of our Trek Field Knife, Keydex & Cinch Belt allows us to create more products in the minimalist gear industry. If you have been following along since the beginning you know that back in 2013 we started out with the goal of bringing a metal minimalist wallet to the market.

Our first wallet was two simple flat plates, some elastic and some paracord. From the very beginning the priority was simplicity, function and durability above all else. Fast forward to the end of 2019... we have created, tested and brought over two dozen new products to market. How do we continue to create new products?

We wish there was a simple answer opposed to a complex system of moving parts. There is one truth we contribute the success - to you, the supporter of Trayvax products and our amazing employees. We thank you Trayvax employees and supporters for bringing products to market that everyone can enjoy.

Everything Starts With an Idea:

Each new product creation is accompanied by a system to make the production process seamless, efficient and effective. Before any product gets the green light to production we scheme up a prototype. The best way to build any physical product is to document your ideas and try to get those ideas in your hands as timely as possible. These ideas can start as "warehouse talk" to pass the time as we hand-stitch products, pressure stamp leather cutouts or box up gear to be shipped out. And before we know it we have created a prototype, endlessly tested it and released it to the market.. like our new Trek Field Knife. Other products are created to minimize wasted material, we can not stand throwing away material. Products like our Leather Wristlet and Cord Wranglers were created to aid in making life easier; but they also allow us to use the most of our leather hides. We do not want to waste an inch of leather, creation of these convenient products allows us to use more and waste less!

Prototype to Launch:

As the creative juices start flowing, fine-tuning a prototype can be the most rewarding part. Excitement for creating something brand new sparks a drive to work smarter and longer. Every material used for the new product is examined and we determine whether it will hold up against the test of time. After all, our products are backed by our 65-year heirloom warranty, it needs to fit the Trayvax Standard. Thus, before launching we endlessly test durability, functionality and simplicity of the everyday-carry product.

Upon deciding a product is ready for market we create a system internally to manufacture the product. Which can take some brainstorming as every inch of our US based warehouse is accounted for. If necessary our CNC-machine will get to work creating inventory blanks. We will create a custom pressurized stamp to perfectly cut the leather. Then conduct a step-by-step process for our employees to begin assembling the product by hand. We setup different stages of creation so that each product is inspected by multiple eyeballs to insure that only the highest quality is shipped out the door.

Post Launch:

After we create the prototype, a manufacturing process and release it to the public we continue improving our systems. Such as, tweaking the ways our CNC-machine cuts into different types of material, what tool used in the machine for each product, the spacing of each leather cutout or ways to completely revamp a product entirely. Learning never stops at Trayvax. We hold each other to a standard of continuous improvement. We simply can not accept that we perfected any step of product creation, thus pushing us to always be innovating new ways to maximize our systems.

Cheers,

Brian Zig - Trayvax Content Creator

More Trayvax Blog Posts

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.